The microscope designed for observing internal surfaces, such as hole walls and rail interiors, allows for a 360° view in a single shot. Here are its key features:

1. Features of the Hole Wall Inspection Microscope

Feature 1: Utilization of a 178° Field of View Hole Inspection Lens

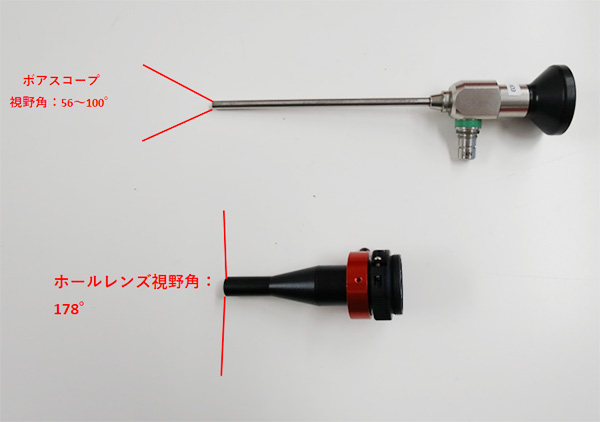

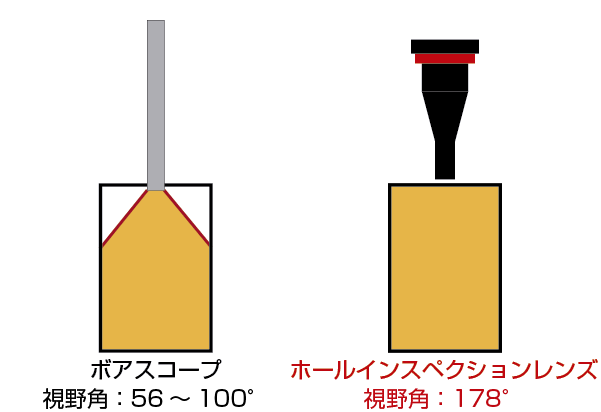

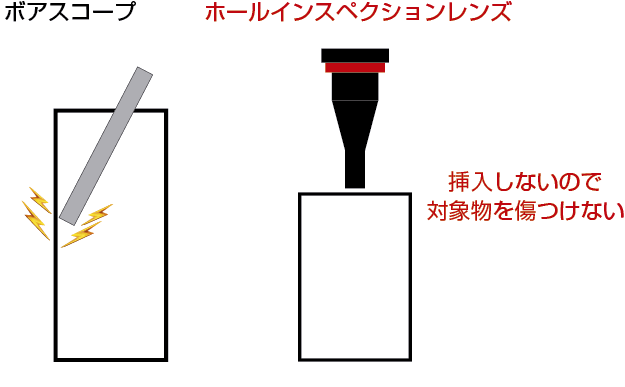

When observing inside holes, it’s common to use a borescope. Borescopes typically offer a standard field of view around 60°, and up to about 100° for wide-angle types. In contrast, the hole inspection microscope utilizes a hole-in inspection lens with a field of view of 178°.

(Understanding that the hole inspection lens will be discussed in the next section.)

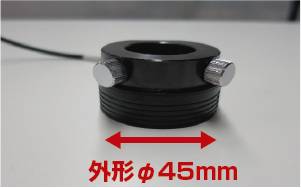

Feature 2: Utilizes ultra-small diameter LED ring illumination tailored to accommodate hole diameters

|

|

|

|

Optimal for hole diameters ranging from φ50 to 100mm and depths up to 100mm, featuring ultra-fine LED ring illumination. |

|

2.What is a Hole Inspection Lens?

Point 1. Viewing angle: 178° wide-angle lens

The viewing angle is a whopping 178°.

As shown below, the field of view expands at almost horizontal angles.

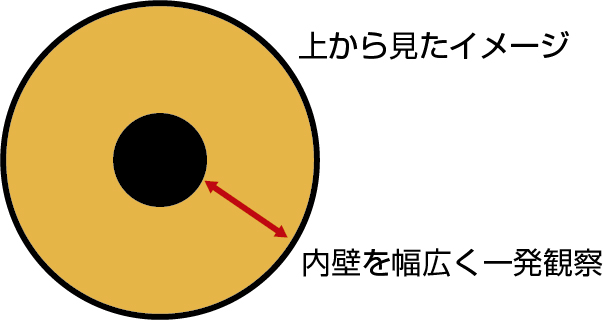

Point 2. 360° entire circumference observation possible

The fisheye effect allows you to observe a wide range of interior walls in one shot.

Point 3: High Depth of Field

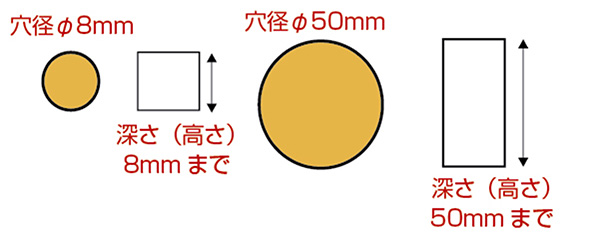

The hole diameter ranges from φ8mm to φ50mm, with a depth approximately equal to the diameter (e.g., about 50mm deep for a φ50mm hole) being the limit.

We employ lenses inherently possessing a deep depth of field. Additionally, adjustment of the depth of field is feasible with an integrated aperture mechanism.

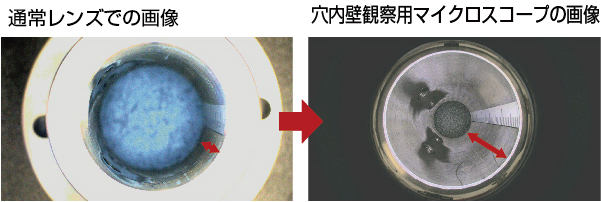

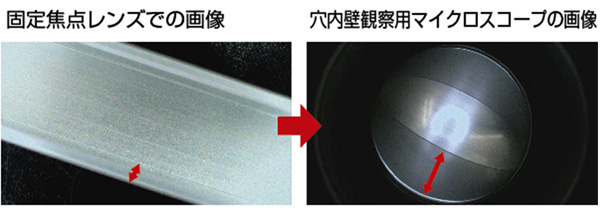

When compared to images captured with fixed-focus lenses, the greater depth of field becomes evident.

Point 4: Observation of Inner Hole Walls Without Inserting Lens into Every Hole

The Hole Inspection Lens offers a wide field of view at 178°, eliminating the need for insertion into each hole. Even at the entrance or with minimal insertion, the risk of damaging the object is significantly reduced.

3. Summary of the Internal Wall Observation Microscope

The internal wall observation microscope maximizes the features of the “Hole Inspection Lens” and “Ultra-Small Diameter LED Ring,” enabling a comprehensive 360° inspection of the inner walls of holes in a single operation.

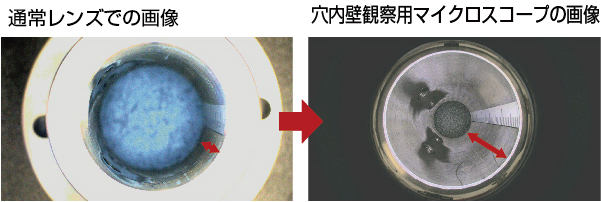

Point 4: Observation Images from the Internal Wall Observation Microscope

● Observing the Inner Wall of a φ30mm Flange

|

|

|

|

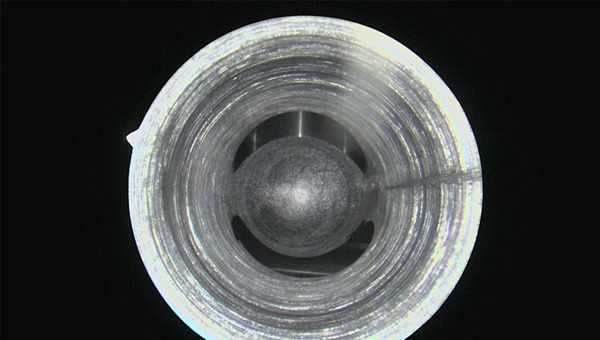

●Observing the Inner Walls of a C-shaped Rail

|

|

|

|

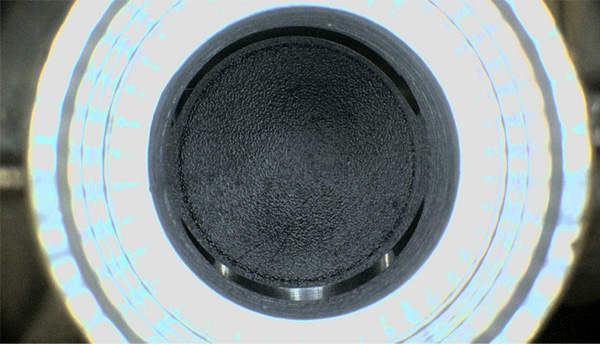

● Observing Engine Surrounding Components

I observed the inside of a φ45mm diameter hole.

< (Reference) Inspection Image of a Zoom Lens Type Digital Microscope >

|

Light enters the hole, but the inner walls of the hole are completely invisible. Thus, inspection cannot be conducted. |

< (Reference) Inspection Image with Borescope Camera >

|

Light enters the hole, and the view is clear towards the distal end (0° direction), but the depth at which the inner walls of the hole are visible is shallow. To improve this, it’s necessary to adjust the insertion depth of the borescope from front to back. |

Inspection Image with the Internal Wall Observation Microscope (PHL200BA)

Thanks to the adoption of ultra-small diameter LED ring illumination, light enters the hole effectively, allowing for clear visibility. The depth range of approximately 0 to 50 mm is in focus all around in a single operation, enabling clear observation of cross holes as well. The area around the cross holes is also observed thoroughly.