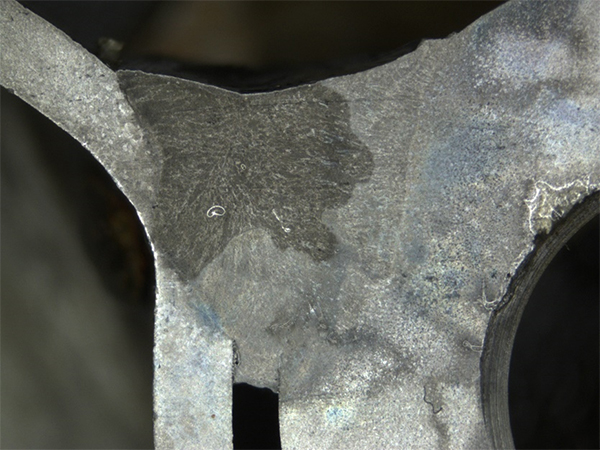

Welding is an important means of bonding metals, and the weld part is very important because it is directly related to the safety of the product.

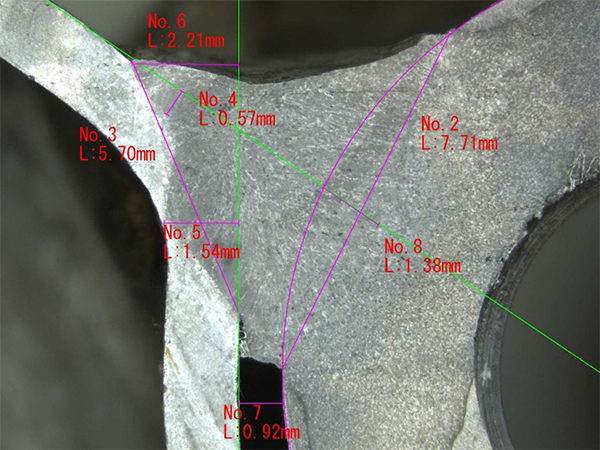

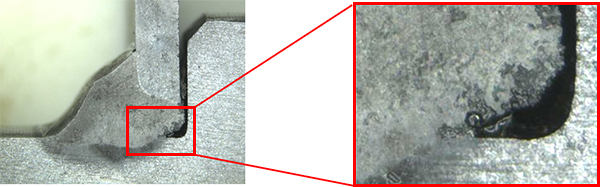

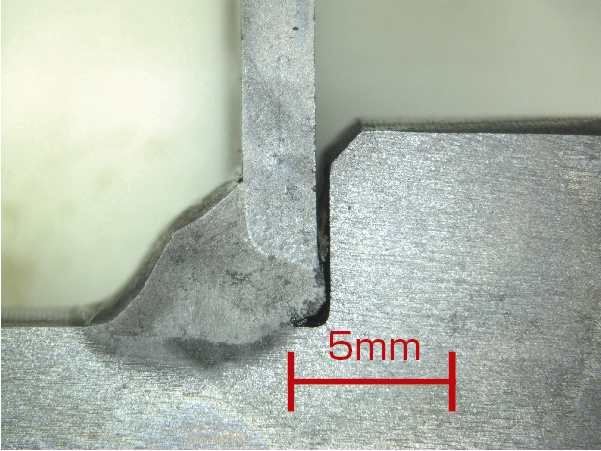

Therefore, the amount of penetration of the weld is inspected, i.e. dimensional measurements are taken to confirm the depth and quality of penetration. Identify problems such as insufficient penetration, incomplete weld fusion, gaps, and excessive swelling.

<Preprocessing>

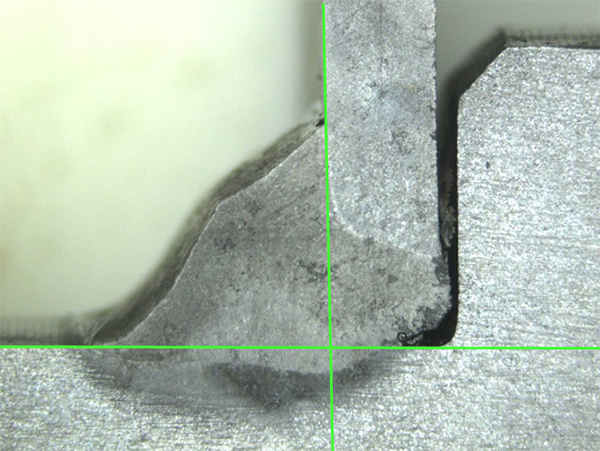

In order to properly inspect the penetration in the cross-section of the weld, the following pre-treatment is required:

① Cutting the test part

② Polishing the cross-section

③ Etching treatment with chemicals or electrolysis according to the material

After these pre-treatments, observations and dimensional measurements are carried out. These preparatory tasks are often entrusted to specialists, but this time we will present a product that specializes in dimensional measurement of the amount of penetration of welds.

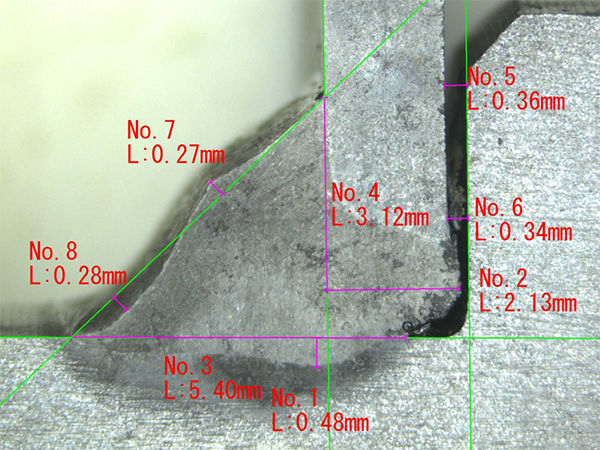

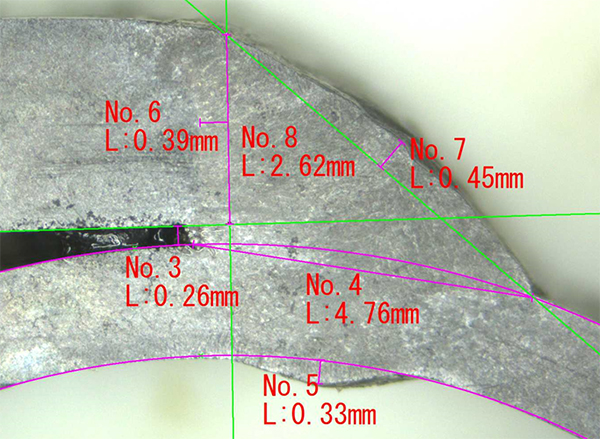

<Imaging and Dimension Measurement>

Specifically, we used our microscope to capture and dimension measurements.

In this process, you need to repeat the following steps:

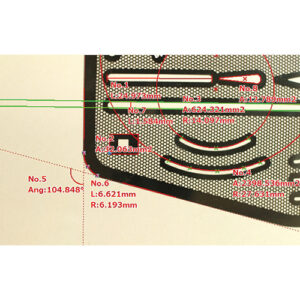

● Generate a reference line

● Measure the distance from the intersection of the reference lines

●Generate parallel lines

● Measure the vertical distance from the reference line

When dealing with a large number of specimens, this task can be quite time-consuming.

However, when using our measurement software, the following measurement support functions are enhanced, and it is possible to improve the efficiency of the time-consuming measurement work of the amount of weld penetration.

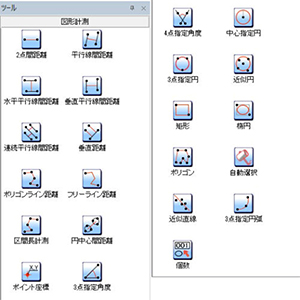

<Functions of the measurement software used in this study>

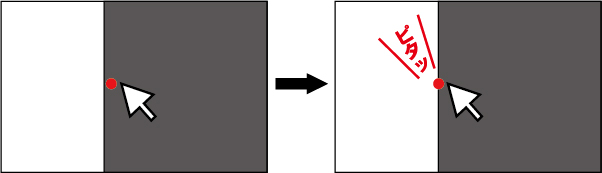

① Occurrence of cross lines

By clicking the mouse on the screen, a cross line will appear at any position.

|

If the position is misaligned, you can easily repeat the click to adjust the position. |

② Abundant measurement items

It is equipped with a wide range of measurement functions and can be used not only for measurement tasks, but also as a reference line.

In this case, you can set the display of the measured value to be hidden.

This feature is particularly useful for measuring “vertical distances”.

In addition, the display color of each measuring line or numerical value can be changed individually.

|

● Distance between two points ● Distance between parallel lines ● Horizontal parallel distance ● Vertical parallel line distance ● Vertical distance ● Distance between the centers of the circle ● Point coordinates ● 3 point specified angle ● 4 points specified angle ● 3 points designated circle ● Approximate circle ●Rectangle ● Ellipse ● Approximate straight line ●Three-point arc etc |

③ Edge auto-fit function

When the mouse cursor is brought close to the desired measurement line, edge detection is automatically performed and the cursor fits the line.

This minimizes errors during the measurement process and results in more accurate measurements.

④ Pinpoint digital zoom function

You can use the mouse wheel to digitally zoom around the position that the cursor is pointing to.

This allows for intuitive scaling and further reduction of measurement errors.

⑤ Scale display

You can display the scale at any position at the desired size.

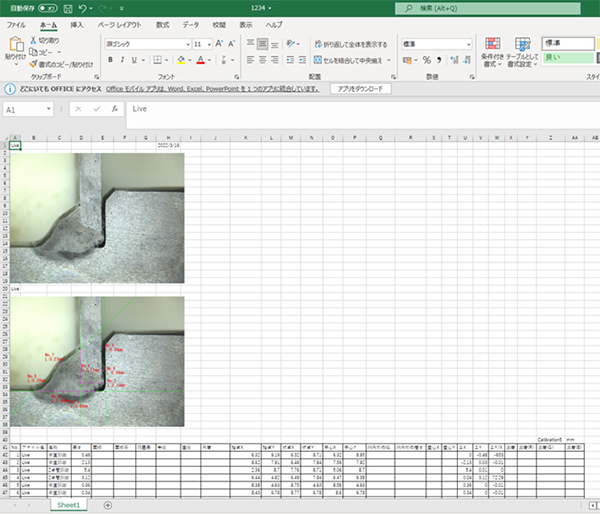

⑥ One-click one-shot reporting function

Simply click the Print to Excel button to transfer the measurement data to Excel. This makes it easier to process data and create charts in Excel, which helps reduce reporting time.

It is very convenient to output raw images, images with measured values, and measurement values to Excel at once.

This is the measurement software used this time

| ● High-performance image processing measurement software MF Ship |  |

This is the microscope used this time

| ● USB3.0 Microscope TG500CS |  |