黒鉛球状化率測定

1. Graphite Spheroidization Ratio

Metal materials are used in various fields, and there are many types of metals. It is essential to select the appropriate material according to the application and purpose. One such metal material is cast iron.

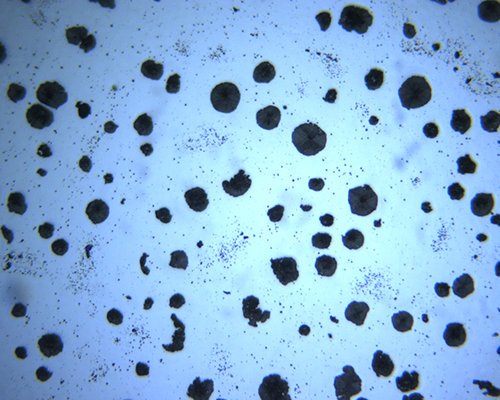

Cast iron is a composite material in which graphite (a non-metal) is three-dimensionally dispersed within steel. The mechanical properties, such as tensile strength and elongation, as well as physical properties like thermal conductivity, vary depending on the shape of the graphite present. Notably, mechanical properties such as tensile strength and elongation require a graphite spheroidization ratio of at least 80% on average, as observed under a microscope at 100x magnification. Therefore, the graphite spheroidization ratio is a crucial evaluation criterion to ensure tensile strength and elongation.

2. Methods of Analyzing Graphite Spheroidization Ratio

The procedure for analyzing the graphite spheroidization ratio involves the following steps:

1. Preprocessing step: Rough cutting for large samples

2. Preprocessing step: Embedding in resin

3. Preprocessing step: Cutting the sample

4. Preprocessing step: Coarse polishing of the cut surface

5. Preprocessing step: Fine polishing of the cut surface

6. Preprocessing step: Buff polishing for a mirror finish on the cut surface

7. Preprocessing step: Etching treatment with chemicals (burning the surface with chemicals)

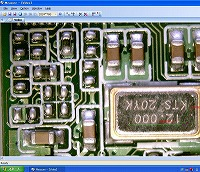

8. Microscope observation

9. Classification, counting, and calculation

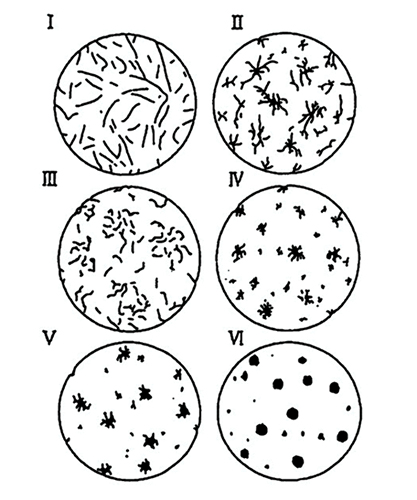

The preprocessing steps are numerous and time-consuming. For observation, a metallurgical microscope is used, and microscope observation is conducted at 100x magnification. Classification and numbering are performed using the roundness factor standardized by JIS industrial standards.

Using these methods, the area calculation and counting are performed to determine the graphite spheroidization ratio.

The calculation of the graphite spheroidization ratio in the microstructure is performed as follows:

1. The magnification is set to 100x in principle, and the analysis is conducted over five fields of view to determine the average value.

2. Graphite and inclusions less than 2 mm (actual dimension 20 μm) are excluded from the analysis.

3. Comparison is made using a classification table.

4. The graphite spheroidization ratio is calculated as the percentage (%) of graphite particles with shapes V and VI relative to the total number of graphite particles.

This method is analog, requiring complex and time-consuming tasks. Including preprocessing steps, the process demands significant time and effort, is prone to human error, and makes evaluation challenging.

3. Improving the Efficiency of Graphite Spheroidization Ratio Analysis

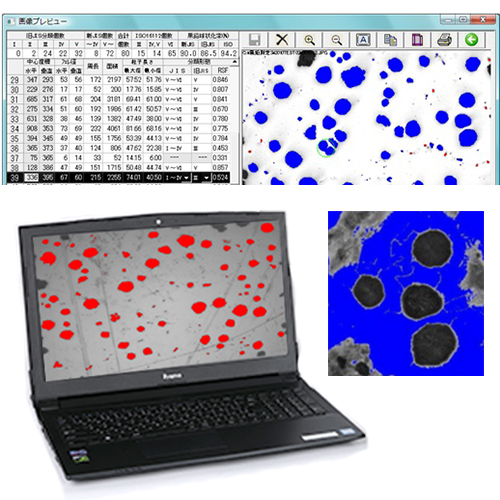

We propose a method using graphite spheroidization software. This approach involves capturing clear images of spheroidized graphite under a microscope and analyzing them with software. The analysis adheres to the aforementioned calculation methods through image processing. Various shapes and sizes of spheroidized graphite can be identified in the images. Additionally, the software can automatically measure the area and count the graphite from these high-resolution images. Moreover, the software can export the static images and precise values in an Excel format, streamlining the entire process of report creation.

For more details on the graphite spheroidization ratio measurement software, please refer here.

|

Graphite Spheroidization Ratio Measurement Software (Nippon Steel Technology Co., Ltd.) KKS04 |

4. An Efficient Set for Analyzing Graphite Spheroidization Ratio

Recommended for those who need to analyze large cast iron samples, prefer portability, and want a simplified method for measuring the graphite spheroidization ratio!

● Set includes a compact, easy-to-use metallurgical microscope with a camera, and graphite spheroidization ratio measurement software.

|

Compact and Portable Metallurgical Microscope KKKI-STD6-130DN ● Easy observation of large cast iron samples

|

|

|

|

Graphite Spheroidization Ratio Measurement Software (Nippon Steel Technology Co., Ltd.) |

Highly recommended for those who want a more comprehensive approach to measuring the graphite spheroidization ratio!

● Set includes a metallurgical microscope, a microscope camera, and graphite spheroidization ratio measurement software.

|

Inverted Metallurgical Microscope (Ultra-High Magnification) GR-29J-C3J |

|

|

|

|

|

|

|

Graphite Spheroidization Ratio Measurement Software (Nippon Steel Technology Co., Ltd.) |

5. Conclusion

Using software for measuring the graphite spheroidization ratio is highly efficient. We offer both convenient, simplified sets and comprehensive, advanced sets to meet your needs.

。