1. Crystal granularity is

There are many types of metals and it is necessary to choose the right metal material according to its use and purpose.

For example, automobile engine parts and general metal parts use different metal materials.

This is because mechanical properties (such as strength against external forces such as tension and shear) vary greatly depending on the metal material.

To evaluate this metal property, it is necessary to observe the crystal structure of the metal structure.

The metallic structure is a polycrystalline structure with a crystalline structure consisting of crystalline grains.

In the space between crystal grain and crystal grain there are disordered patches and the boundaries of those patches are grain boundaries.

The granularity of this crystal grain (crystal grain degree) is an important factor that determines the mechanical properties of that metal material.

In general, crystallinity refers to the “magnitude of crystal grains” in materials such as metals.

Furthermore, metal structure changes not only by the type of metal material such as aluminum, iron and alloys but also by heat treatment.

Even when the metal or alloy is of the same type, heat treatment will cause the crystalline grains to align in a specific pattern, forming grain boundaries that are different from those before heat treatment.

Therefore, heat treatment changes the grain size and changes the mechanical properties and properties of the metal.

Therefore, grain size analysis is an important test to ensure metal product quality.

・Austenitic granules

Consists of twin crystals annealed in the crystal grains of the central face of the cube

・Ferrite beads

Does not include twin crystals annealing in the rim line of the centrosomal face

2.Particle size analysis method

①Visual comparison between standard diagram and metallurgical microscope (comparison method)

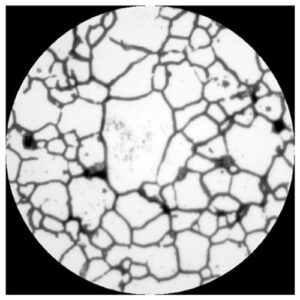

We perform pretreatment such as polishing the metal surface and observe it with a metallurgical microscope.

Grain size was estimated by visually comparing the metal structure magnified by a metallurgical microscope with the “Austenite Grain Size Standard Diagram for Steel (x100) JIS G 0551”.

|

Metallurgical microscope |

However, you have to take your eyes off the metallurgical microscope for a while, which is troublesome.

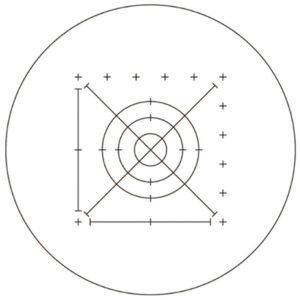

②Comparison of simultaneous observation by incorporating an eyepiece micrometer into a metallurgical microscope (comparison method)

Insert an eyepiece micrometer (reticle) with printed grain size sample into the eyepiece of the metallurgical microscope, and visually observe and compare the enlarged sample and the grain size standard sample to determine the grain size .

This is easy because you can simultaneously observe and compare without taking your eyes off the metallurgical microscope.

|

Particle size scale R1901 manufactured by Shibuya Optical Co., Ltd. |

③Calculation by incorporating an eyepiece micrometer into a metallurgical microscope and comparing simultaneous observations (counting/quadrature method, cutting method)

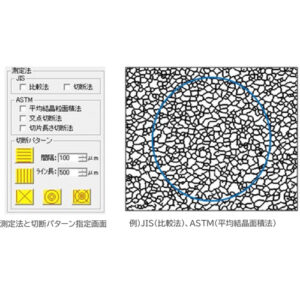

An eyepiece micrometer (reticle) with the pattern printed below is inserted into the eyepiece of a metallurgical microscope, the magnified sample and its pattern pass inside the crystal grain, creating an average line per crystal grain. The method complies with JIS G0551/ASTM E112 standard for length determination and particle size calculation.

|

Manufactured by Shibuya Optical Co., Ltd. Steel R2010-24 – Grain size test method scale (cutting method) |

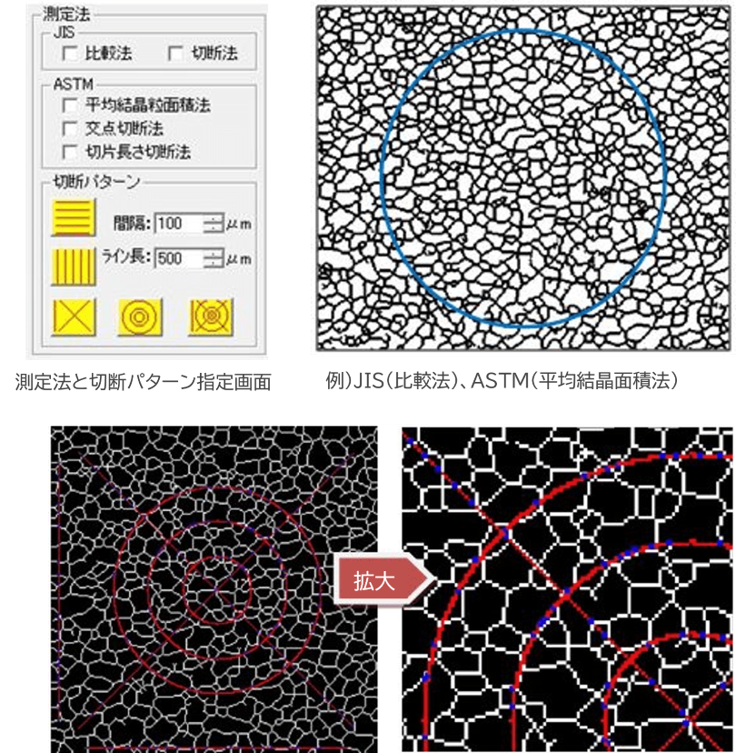

④Measuring particle size with software using camera (compatible with comparison method, counting/quadrature method and cutting method)

Additionally, a microscope camera is attached to the metallurgical microscope and automated measurements are performed using the following measurement software.

This method allows automatic and very effective measurements.

|

USB3.0 microscope camera (5 million pixels) |

|

G-S Measure particle analysis software (produced by Nippon Steel Technology Co., Ltd.) |

|

◆G-S PARTICLE ANALYSIS SOFTWARE FOR Particle SIZE MEASUREMENT 【Comply with JIS and ASTM standards!】 This is a particle size assessment tool that complies with the following standards. ・ASTM standards (ASTM E 112-96, ASTM E 1382-97)

【Can measure up to 12 types of particle sizes!】 ・The evaluation method is to perform up to 12 measurements at the same time by combining the cut samples and calculating the number of grain sizes. 【Cutting pattern can be selected from 5 types!】 ・For cutting method, you can choose from 5 cutting patterns and set spacing and line length.

【Useful for making reports! Excel Output】 ・Particle size measurement results can be exported to Excel (CSV format).

ASTM (intersection cutting method, intersection length comparison method) In the display after measurement, areas with grain boundaries overlapping the cut sample are displayed in blue. *Image example is a 1000×1000 point scope measurement with 100x microscope magnification. |

3.Conclusion

If particle size analysis is not routine, using an eyepiece micrometer is a cost-effective method.

If you do this regularly, there will be initial costs, but we recommend using a microscope camera to automate measurements with software, as it automates and saves labor.

The software also has other useful functions.