1. Crystalline Grain Size

There are various types of metals, and it is necessary to select appropriate metal materials based on their intended use and purpose. For instance, the metal materials used in automotive engine parts differ from those used in general metal parts. This is because different metals exhibit significantly varied mechanical properties (such as resistance to tensile, compressive, and shear forces).

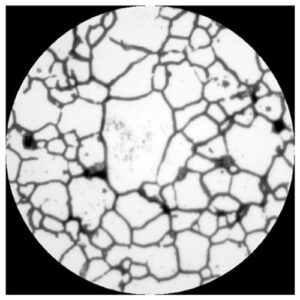

To evaluate these mechanical properties of metal materials, it is essential to observe the crystalline structure of metals.

Metal structures consist of polycrystalline structures composed of crystalline grains. There are regions between these grains where the arrangement is disordered, and these boundaries are known as grain boundaries. The size of these crystalline grains (grain size) is a crucial factor that determines the mechanical properties of such metal materials.

Generally, crystalline grain size refers to the “size of the grains” in materials like metals.

Furthermore, metal structures change with heat treatment, not just based on the type of metal material like aluminum, iron, or alloys. Even within the same type of metal or alloy, heat treatment arranges the crystalline grains into specific patterns, forming grain boundaries different from those before heat treatment. Therefore, heat treatment alters the crystalline grain size, thereby changing the mechanical properties and characteristics of metals.

Consequently, the analysis of grain size is a critical inspection for ensuring the quality of metal products.

・Austenitic Crystal Grains

Face-Centered Cubic (FCC) crystal grains containing annealing twins

・Ferrite Crystal Grains

Body-Centered Cubic (BCC) crystal grains without annealing twins

2.Methods for analyzing crystal grain size

1. Visual Comparison between Standard Chart and Metallographic Microscope

The metal surface is prepared by polishing, followed by observation under a metallographic microscope. The grain size is estimated by visually comparing the enlarged metal structure observed through the microscope with the “Austenite Crystal Grain Size Standard Chart for Steel (×100) JIS G 0551.”

|

金属顕微鏡の詳細はこちら |

However, it is cumbersome as it requires temporarily looking away from the metallographic microscope.

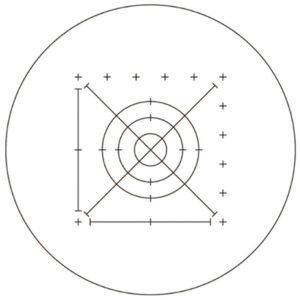

②Integration of Eyepiece Micrometer into Metallographic Microscope for Simultaneous Observation and Comparison (Comparison Method)

Insert an eyepiece micrometer (reticle) with grain size patterns printed on it into the eyepiece of the metallographic microscope. This allows for simultaneous visual comparison between the enlarged sample and the grain size standard pattern. By observing them concurrently without needing to look away from the metallographic microscope, the grain size can be estimated comfortably.

|

|

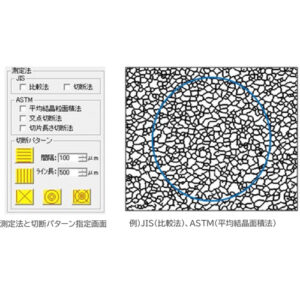

3. Incorporating an eyepiece micrometer into a metal microscope for simultaneous observation and comparative measurement (counting / planimetric method, intercept method).

Insert the eyepiece micrometer (reticle) with the pattern printed as shown below into the eyepiece of the metal microscope. Determine the average line segment length per crystal grain crossing through enlarged samples and their patterns, calculating the grain size in accordance with JIS G0551/ASTM E112 standards.

|

Shibuya Optical Co., Ltd.’s R2010-24 Steel – Grain Size Testing Scale (Sectioning Method) |

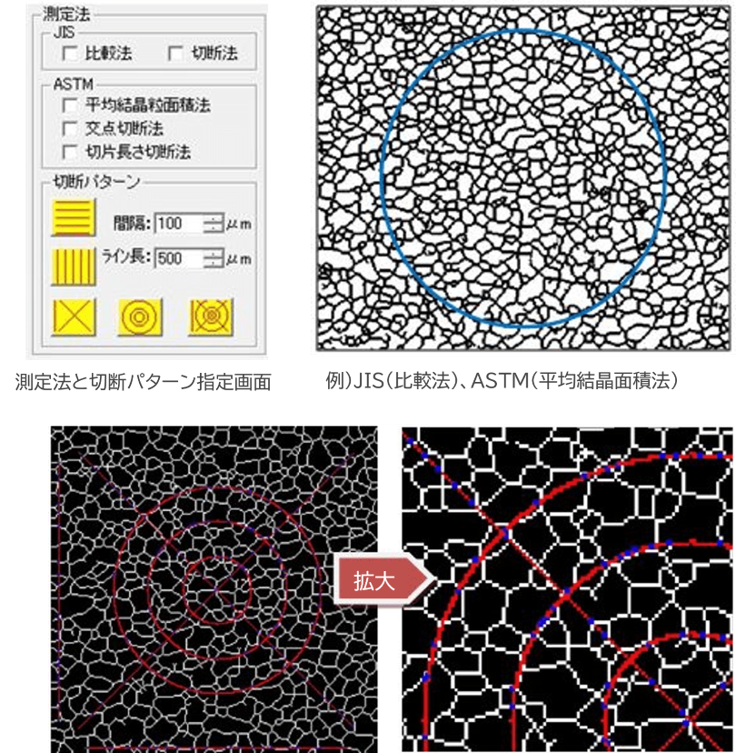

④ Using a camera to perform particle size measurement with software (comparative method, counting / planimetric method, intercept method)

Furthermore, attaching a microscope camera to the metal microscope and performing automatic measurements using the following measurement software.

This method enables automated measurements, significantly enhancing efficiency.

|

For details on the USB3.0 camera for microscopes (5MP), click here. |

|

For details on the particle analysis software G-S Measure (manufactured by Nippon Steel Technology Co., Ltd.), click here. |

◆ Particle Analysis Software G-S Measure for Grain Size Measurement【Compliance with JIS and ASTM Standards!】

This tool evaluates grain size based on the following standards:

【Up to 12 Different Grain Size Measurements Possible!】

– Evaluation methods allow simultaneous measurement of up to 12 patterns using combinations of cutting patterns, enabling calculation of grain size numbers.

【Choose from 5 Cutting Patterns!】 – In the sectioning method, you can select from 5 cutting patterns and adjust intervals and line lengths. 【Convenient for Report Generation! Excel Output】 – Measurement results for grain size can be exported to Excel (CSV format), facilitating report creation.

<Measurement Display Example> ASTM (Intersection Sectioning Method, Slice Length Comparison Method) After measurement, the display highlights grain boundaries in blue where they intersect with the cutting pattern. |

3.まとめ

結晶粒度解析の頻度が少ないのであれば接眼マイクロメーターを使用する方法が

費用を抑えられます。

頻度が多いのであれば初期コストがかかりますが顕微鏡カメラを使ってソフトで

自動測定する方法が自動化・省力化できて、オススメです。

ソフトにはさらにこんな便利な機能もあります。