This article presents the key points, usage, and recommended microscope models for using the measuring capabilities of microscopes in the context of quality control.

Important points

Although some microscopes are equipped with measurement capabilities,

However, their use can be difficult due to the following two problems

(1) Microscopes themselves may not be measuring instruments that guarantee traceability.

(2) Except for high-performance models, calibration must be performed by the end user.

(This may lead to errors due to user manipulation.)

How to use

When used for quality control purposes, there is no problem if in-house calibration is performed.

However, in such cases, the reference standard used should be clarified.

In short, use is feasible if the following three conditions are met.

・Select a microscope with high reproducibility.

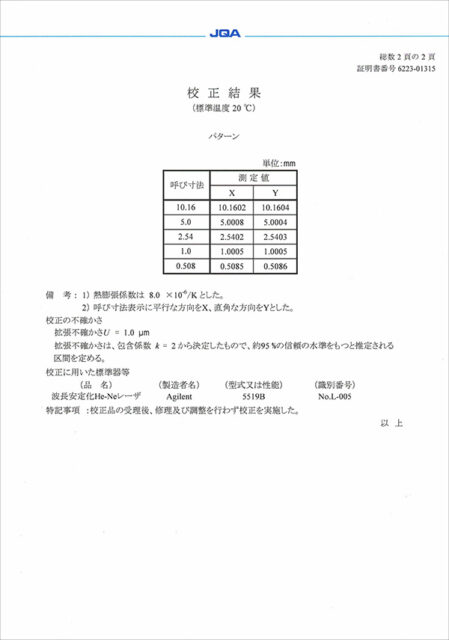

・A reference standard that can confirm the accuracy of the selected microscope is clearly available.

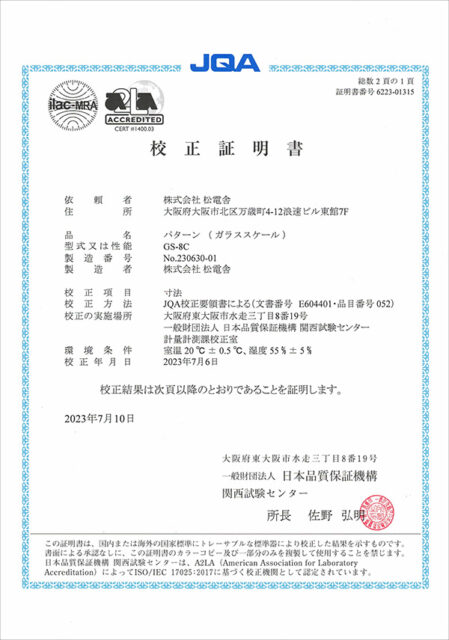

・The company possesses a traceable reference standard.

ISO 9001 certified companies also use these standards.

Recommended microscopes

For the use of length measurement functions in quality control, we recommend the

CT200HD series microscopes

◆Adoption of the interlocking system between the lens and camera, which is rare in the middle class

Data from the lens is transferred to the camera, which automatically utilizes the built-in calibration data.

・No need for user adjustments

・No measurement value discrepancies caused by user operation

◆Optional dedicated glass scale for checking accuracy

Calibration certificates and test reports can be provided for glass scales (for a fee).

|

|